Concept Prototyping for Hardware

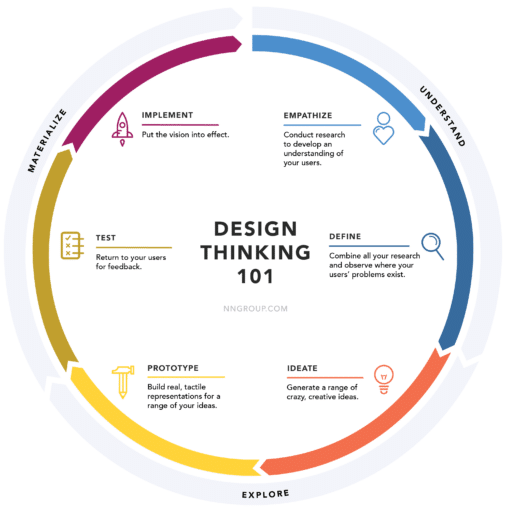

You’ve probably heard of prototyping, however, the topic is broad and means different things to different people. In this article, we’ll refer to concept prototyping. Specifically for hardware devices, and as a subset of the Design Thinking process. From a 30,000-foot view, this type of prototyping typically starts with insight into a problem or opportunity. Beyond that, a team evaluates the problem statement and develops a few ideas to solve it. The following steps involve building, testing, and evaluating to see if the concepts hold any water — figuratively speaking.

The value of concept prototyping

One of the most prevalent challenges in product creation is moving from PowerPoint to the first tangible hardware prototype. This process is often costly and time-consuming. However, the longer you delay taking this step, the higher the expectations.

We have a unique approach to concept prototyping. One that solves this challenge by putting something tangible in the decision maker’s hands sooner. An actual object simply evokes a different response to a concept sketch or a PowerPoint document. The sooner you can see and feel, the sooner you can evaluate for potential.

We’re referring to a rapidly built, low-fidelity prototype focused on solving specific problems (instead of complex issues). These prototypes lead to a faster and more effective design cycle, making it easier to identify problems early, avoiding costly mistakes down the road.

Diagram courtesy of the NNgroup.

Prototyping and testing an early concept, allows you to challenge your assumptions with actual end-users and capture their valuable feedback. It helps you to gauge the market’s appetite and expectations for your idea. It also provides the validation needed to advance to the next phase before investing in an unproven concept.

Receiving customer validation is essential in any CX cycle as it keeps you on track to satisfy the market’s needs. When it comes to innovation, it really is better (cheaper) to fail early on.

A closer look

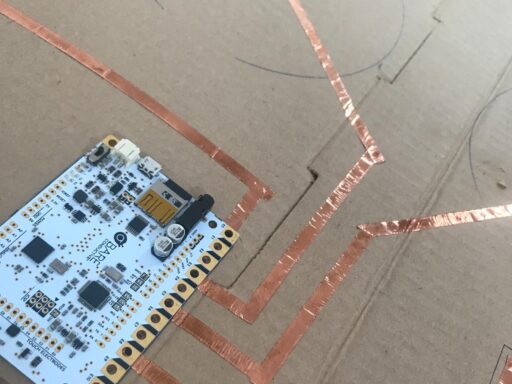

We thrive on finding creative angles to a challenge. Through trial and error, we’ve realized the benefits of prototyping sooner by taking prototyping at a lower fidelity. Some organizations choose to prototype a concept via 3D printing. We blend the physical with Digital on readily available materials. Doing so allows us to rapidly turn seemingly ordinary objects into smart objects with agility and minimal investment. Our methods are ideal for validating early concepts against three pillars of innovation: Desirability, Feasibility, and Viability. Our approach allows us to shape an early idea into a verified concept. One with real proven potential to increase efficiency, comfort, and safety. There is no secret sauce to our methods or process either. We simply use creativity to bring an idea to life quickly and at little expense.

Let’s rewind the clock and explain.

Humble beginnings

Although we have been tinkering with concept prototyping for over 15 years, we recently stumbled onto something fascinating. While I was creating fun Halloween props to entertain my 6-year-old, I discovered a material that turned ordinary surfaces into interactive experiences. I painted a fun message onto a cardboard surface to encourage the daring Trick-or-Treater to touch the sign, which, in turn, played a spooky sound. Yes, you read right. Touch-sensitive cardboard! Delighting our unwitting Halloween subjects provided all the validation I needed. The seeds of creativity began to germinate.

Realizing the potential

Our first opportunity to apply our newly learned skills to a business context arrived when a friend asked us to help his team develop an early concept prototype for a touch-activated midi drum set.

Our low-fidelity prototyping was offering more value than we had previously imagined, and we began to see everyday objects in a whole new light. So far, our low-fi hardware prototypes had incorporated interactive interfaces; impressive as that was, we realized that there was another type of interface that we hadn’t investigated yet. Passive interfaces don’t require human interaction and allow us to detect changes in a surrounding environment to trigger a response. Passive interfaces opened up a whole new realm of prototyping possibilities. Surfaces like floors, walls, windows, furniture, and even vehicle interiors were now options.

These concepts are relatively easy to prototype using basic and low-cost materials and a little ingenuity.

What began as a hobby had a proven commercial value; Our ability to help product managers fill a real gap between the world of PowerPoint and a tangible first draft.

The fine line between What vs. What not

Not all interactive concept prototypes need to involve tech. For example, we recently developed an early prototype of a new mobile form factor where our brief focused on the customer’s overall experience.

Based on the project’s parameters, we realized that we did not need a high-tech solution. Instead, we began our prototyping from a plain old notepad. We sought out a notepad of similar proportions, and we were able to evaluate the ergonomics of the form factor and suggest layout tweaks to the team. These suggestions led us to engage in a dialogue with the engineers about the trade-offs associated with hardware layout changes. We explored several alternatives until we were able to reach a satisfactory solution.

Our notepad also enabled us to recommend customizations of the accompanying Software based on dexterity while holding this new form factor securely. Our goal was to make every interaction feel natural and intuitive in double and single-handed use. The humble notepad carried our team through several weeks of early concept prototyping and helped bridge the gap between PowerPoint presentations and the first Proof of Concept, moving us swiftly from zero to substantial.

Present-day

With several conceptual hardware prototypes under our belt, we’re fully aware that the endless possibilities this form of prototyping offers and the ability to surprise and delight is sky-high. For example, who expects a piece of paper to respond to touch? Or a mural to begin to animate? Or a set of stairs to behave like a piano when you walk on them? But these are the types of experiences that we’re able to prototype, right here in our Vancouver studio.

Over the past year, we’ve adapted our (concept validation) process to fit the new world and replaced our user-testing lab with a more remote-friendly system. To facilitate a speedy turnaround, we now package our prototypes and mail them out to our test subjects with a note asking them only to unbox the package during our video call. Receiving a package is always an exciting moment. Being cooped up at home during pandemic times only adds to this experience. We aim to capture that moment during our online user interviews, observing the test subject’s reactions and body language to their unboxing and first-run experience as we ask them thoughtful questions about their interactions.

This simple shift in our process has enabled us to move quickly and scale our operation.

If you’re looking to develop and test a concept for its potential in the real world, let us help you. Our process of concept prototyping and validation with real end-users is a proven success and has improved the efficiency of many product teams’ design cycles.

Want to talk more? Contact us.